| |

In order to reduce the time it takes for our customers to gear up a manufacturing process, we are offering anend-to-end manufacturing service for M2M products. Our objective is to use our expertise to manage our customers' bill of materials, and the manufacturing process itself. This will free them up to concentrate on product design and ensure that these designs reach the market quickly, and at the right price.

Through partnerships that we have established with local and international factories we are able to offer a manufacturing service for both low volume as well as high volume production.

Services also include project management, professional technical support, extended warranty and web-based applications for maximal optimization of M2M projects.

The contract manufacturing service can offer:

- Plastic moulding: the manufacturing plant produces high precision plastic moulds;

- Tools making: the facility has 92 injection machines and 12 co-injection machines for high precision plastic tooling, co-injection tooling, spray painting, silkscreen printing and simple parts assembly;

- Silicon keypads making: this includes silicon spray coating, polyurethane spray coating, epoxy coating as well as plastic and rubber assembly

- Metal parts stamping: 160 stamping presses for metal parts stamping. Many different types of metals can be accommodated. The Salt Spray Test is conducted on all items to ensure they are rust-proof.

- Products mock-up: using sophisticated software and techniques. Methods such as Stereolithogrophy, Selective Laser Sintering and Fused Deposition Modelling are offered.

The facility follows strict international standards for quality, and performs quality assurance at all stages of the manufacturing process.

For any enquiry, please send an e-mail to: info@wwsinternational.net.

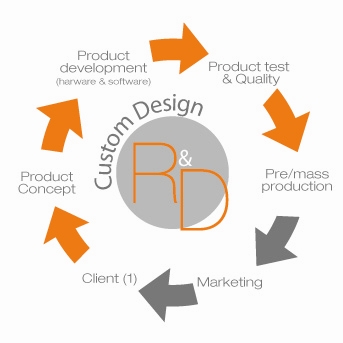

Custom Design

Custom design and OEM projects through our sister company: tailor made developments to meet unique customer requirements offering a complete solution, including hardware and software.

The custom design process:

(1) The client brings his project. We evaluate the feasability, we give some recommendations and we make

a proposition. When the client agrees to entrust us, the custom design process begins.

At the first step, the product is conceptualized; we provide a reference design. Then, during the product development stage, the design is reviewed, the hardware and the software are developed, and the applications and services are defined. At the next step, the product is pre-tested and if it reaches all the requirements, Maestro Wireless Solutions Ltd. could bring it for international certifications (CE, GCF, R&TT, FCC, PTCRB, ...). At the final stage, the product is delivered to the client.

Following the customer requirements, we can help him begin the production, and introduce it on the market.

For additional information, please send an e-mail to: info@wwsinternational.net.

|