Main MenuProductsPartners |

AlertMobile at Roquette Avoid useless travels

World actor of starch and its derivatives, Roquette group chooses AlertMobileRoquette Group processes every year 6 millions tons of renewable raw materials ( corn, wheat, potatoes, peas and tomorrow micro-algae) in a range of over 650 products derived from starch for the human and animal nutrition, paper-board, pharmacy-cosmetology and biochemistry industries. Roquette strongly invests into sustainable development: the Vecquemont site exampleThe Vecquemont plant (near Amiens) is a potato starch plant which treats nearly 1 mil-lion tons of potatoes each year to extract the starch from them. Nearly 50% of the pro-duction is for paper mill, the rest being used in the food industry. The plant, the only one in the group working on potato, shows Roquettes strong com-mitment to its core values of sustainable development, safety and quality. In the sustainable development domain, the plant strives to optimize both the energy inputs necessary for its production and waste. Upstream, a new wastewater treatment plant with biogas production has been built. This wastewater treatment plant, operational since August 2007, covers 60 Tons / Day of COD and 4 Tons / Day of nitrogen (the equivalent of a city of 600,000 inhabitants). The combus-tion of biogas can produce approximately 15% of the steam needed for the production site. Downstream, we give back to the earth what we have taken , says Arnaud Roquette, waste and effluents Production Manager, mainly water, in our case, since it is the main constituent of potato. Practically, the plant produces around 300 to 350 m3 of waste each hour, 24/7, which are returned to nature in sewing form. An even more virtuous action for the environment as the water loaded with organic components provide the additional nutritional complement needed for the crop growth. At Vecquemont, six buried pipelines are distributed twenty miles around the plant. Val-ves spread over this buried network enable to attach retractors which field teams set up every day with rotation systems

AlertMobile Safety, responsiveness and comfort for teams

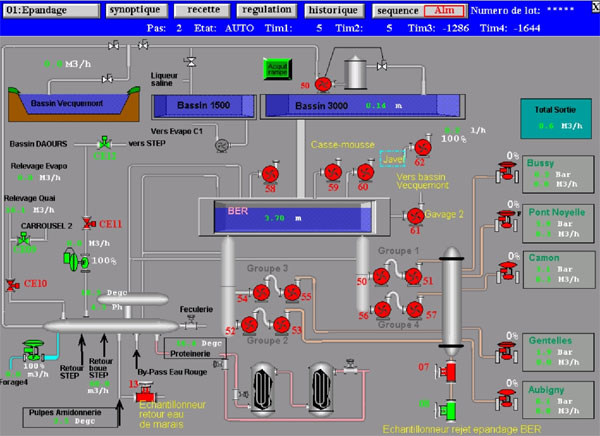

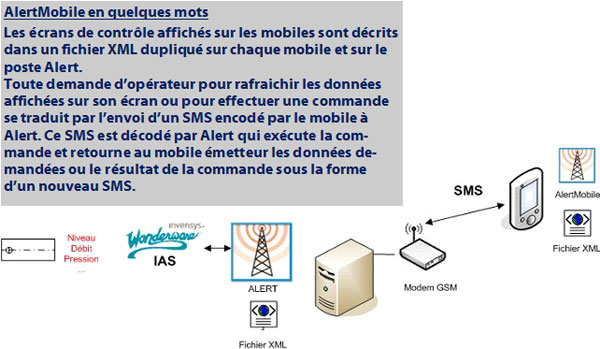

Night and day, two teams are permanently in the field to connect and put in place the re-tractors in the seewing area, and ensure the right functioning of the system controlled by the IAS supervision software. "Flow, pressure, level tray lines , start / stop, systems faults... are ones of many parameters that teams were used to check on the IAS centralized monitors" says Thierry Dambrin. "Our goal with AlertMobile was to provide greater security for our teams by reducing their field trips" he says. "AlertMobile has been integrated all the easier since variables from IAS are easily accessible . Now, thanks to AlertMobile, field teams have a remote supervision to control, open or clo-se valves, and continuously monitor the critical parameters on their smartphones. "A real comfort for our teams, which have considerably reduced their number of traveled kilometers, and therefore the associated accident risks" said Thierry Dambrin. "And with a very easy transition, since the AlertMobile application ergonomy allowed to exactly repro-duce the work environment our engineers were accustomed to". Lastly, the operators have particularly appreciated the stylus which all mobile phones have, it enables them to work without removing their gloves. Safety and work comfort, but also responsiveness since operators can receive alerts direc-tly on their smartphone through AlertMobile and react more quickly when problems occur. Using AlertMobile at Roquette is a perfect illustration of the strong social commitment of the industrial group, both in terms of quality, and environment or human protection, Alert providing both security , reactivity and mobility to one of the most exemplary firms of the subject. AlertMobile in a nutshell The screens displayed on the smartphone are described in an XML file duplicated on each mobile and the Alert server. Any operator requests for a refresh of the data displayed on the screen or to execute a command results in sending an SMS message encoded by the smartphone sent to Alert. This SMS is decoded by Alert which runs the command and re-turns to the emitting smartphone the required data or the result of the command as a new SMS

|

References

Support |